Model: MRC-C

This conveyor is the most common type among motorized roller conveyors for general material handling. It can be cutomized as per specific requirement in specifications, as well as conveyor forms like positive motion, accumulation and sdjustable accumulation. It intends to:

* Increase the efficiency of material handling work* Decrease the intensity of labor, and quantity of labor

* Protect items from manual impact damages

* Save overall cost for modern enterprise management

Application:

General packed goods delivery from one place to the other, goods confluence and diversion transition, assembly and production

Features:

Large, continuous and flexible in material transfering, easy to maintain, durable |

Relative Products: |

|

Common Technical Parameters: |

| Items | Options | ||||||||||

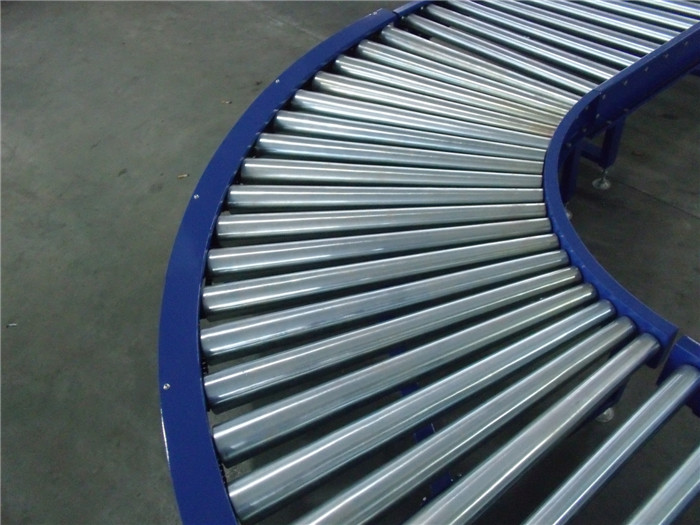

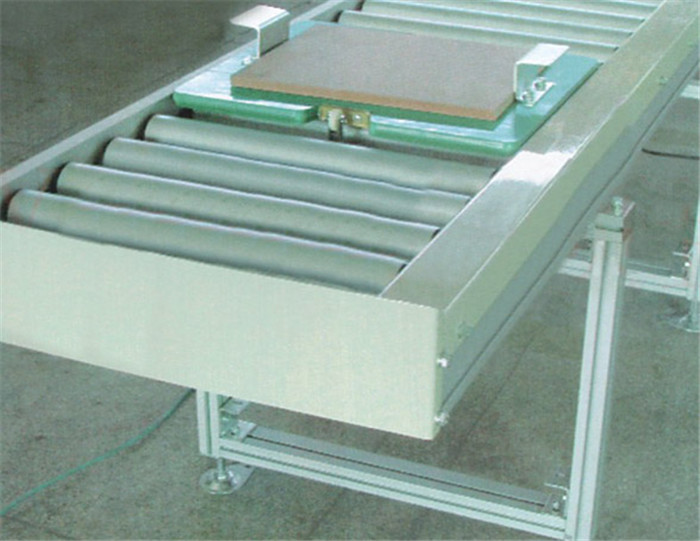

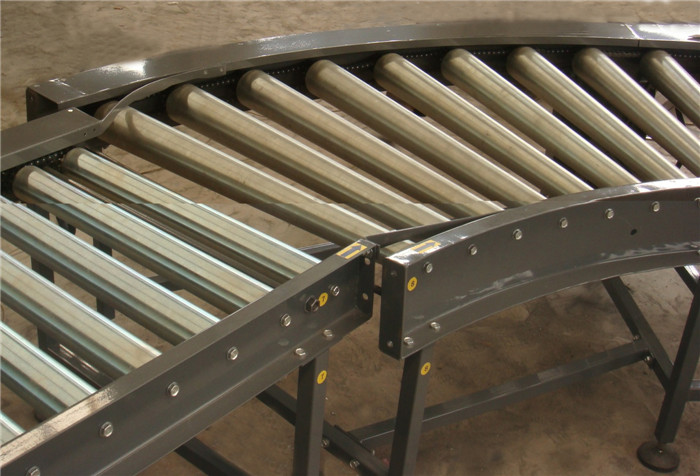

| Conveyor Form | Lineal, Curved, Levered, T-shaped, L-shaped, Z-shaped, C-shaped, O-shaped, etc | ||||||||||

| Roller Type | Zinc-plated, Chrome-plated, Rubber-coated, SUS201, SUS304, Plastic, etc | ||||||||||

| Frame Material | Painted carbon steel, Powder coated carbon steel, Stainless steel (SUS 201, SUS304, SUS 316), etc | ||||||||||

| Conveyor Length | Optional, often 4 meters as one section with one motor | ||||||||||

| Conveyor Width | Optional, 600mm effective as a factory standard | ||||||||||

| Conveyor Height | Optional, 700mm as a factory standard | ||||||||||

| Roller Diameter | Optional, 50mm as a factory standard | ||||||||||

| Roller Distance | Optional, 100mm central as a factory standard | ||||||||||

| Side Frame Overheight | Optional, 50mm as a factory standard | ||||||||||

| Speed | Constant or variable, 10-20m/min as a factory standard | ||||||||||

| Capacity | Optional, 50kg/meter common designed, max. 1000kg/meter | ||||||||||

More Pictures for Reference